Byline: Kotaro Niimi, OSG Corporation Applications Engineer (End Mill Development Division)

In the world of manufacturing, efforts are constantly being made to reduce costs. In addition to high efficiency and long tool life, ability to achieve unattended machining with minimal operator input has also become a highly sought quality in cutting tools in recent years.

Sliding head lathes are highly accurate multi-axis CNC machines that provide a single setup solution for complex processing. They especially excel at producing parts of the same shape with great efficiency and stability. With capabilities to finish delicate parts in one setup and quicker job cycle than traditional fixed head machines, sliding head lathes are one of the best equipment for unattended machining with little or no human intervention.

End mills used in sliding head lathes are generally used for slotting and D-cutting (frontal milling). In spring 2022, OSG has released the AE-VTSS carbide end mill with optimized specifications that contribute to unattended machining operations in sliding head lathes.

Features of AE-VTSS

1. Superior Cutting Chip Control

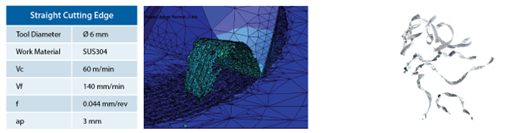

Even if the material removal volume per part is small, chip trouble is likely to arise as the number of work pieces increases. Figure 1 depicts long and distorted cutting chips created by an end mill with conventional (straight) cutting edge geometry from plunging in SUS304. These inconsistent chips may wrap around the spindle as the machining continues. If the cutting chips become tangled around the spindle, the machine must be stopped for chip removal, which leads to reduced productivity.

Figure 1. Cutting chips created by an end mill with conventional (straight) cutting edge from plunging in SUS304.

Figure 2. Cutting chips created by the AE-VTSS end mill with hook shape cutting edge from plunging in SUS304.

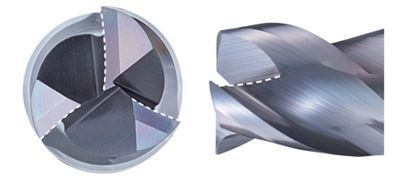

OSG’s AE-VTSS is engineered with an original bottom cutting edge hook shape (PAT. P. in Japan) that contributes to the creation of stable chip shape and improves chip evacuation. The bottom cutting edge of conventional end mills are generally straight, but the AE-VTSS is designed with a bow shape from the outer peripheral side that leads to the center as illustrated in figure 3.

Figure 3. AE-VTSS’s 3-flute specification and bottom cutting edge hook shape.

During product development, cutting simulations were used extensively to determine the optimal specifications of the hook shape. Figure 1 depicts chip generation with a conventional (straight) cutting edge. In contrast, figure 2 illustrates chip generation by the hook shape design. Comparing the two, the hook shape produces chips with stronger curl. In fact, as demonstrated in figure 2, the hook shape produces curled chips in a stable manner, which minimizes chip evacuation troubles such as the tangling of chips with the cutting tool.

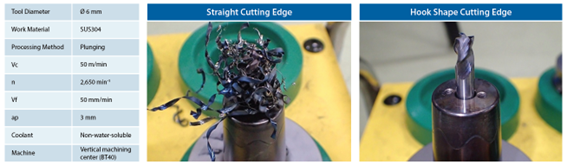

In a cutting trial, the straight cutting edge end mill and the AE-VTSS end mill with hook shape cutting edge are compared by plunging 37 holes continuously. As depicted in figure 4, cutting chips are wrapped around the straight cutting edge end mill whereas the AE-VTSS with hook shape cutting edge is chip trouble-free. As demonstrated in this cutting trial, the AE-VTSS’s hook shape cutting edge effectively suppresses chip evacuation troubles to contribute to stable and uninterrupted machining.

Figure 4. Condition of end mills after plunging 37 holes in SUS304.Cutting chips are wrapped around the straight cutting edge end mill whereas the AE-VTSS with hook shape cutting edge can continued to be used.

2. Multi-functional

The number of cutting tools that can be attached to a sliding head lathe is limited. Taken this characteristic in mind, the AE-VTSS is developed as a multi-functional 3-flute end mill that excels in plunging, slotting and side milling. The multi-functionality of the AE-VTSS contributes to the consolidation of machining processes, reduction of setup time, and tool change time to maximize the performance of sliding head lathes.

3. Variable Lead Geometry to Suppress Vibration

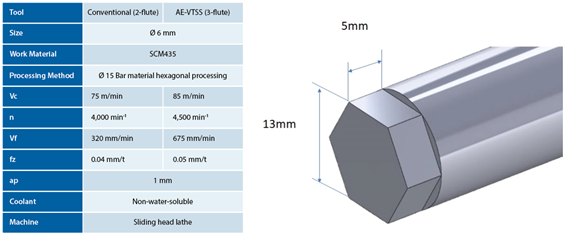

In a sliding head lathe, the workpiece is usually clamped into position by a chuck. Compared to clamping in CNC machining centers, machining with a sliding head lathe has lower rigidity and is more prone to chattering. Figure 5 illustrates a cutting trial between a conventional 2-flute end mill and the AE-VTSS. Chattering and burrs occurred after 2,000 passes with the conventional 2-flute end mill. The AE-VTSS, on the other hand, exhibits stable performance, good machined surface with no burrs even after 3,000 passes at a more aggressive cutting condition. OSG’s AE-VTSS’ unequal spacing of teeth and variable-lead geometry have effectively minimized chattering to enable stable and high-efficiency milling even in a setup with low rigidity.

Figure 5. Cutting condition and work shape image of a cutting trial between a conventional 2-flute end mill and the AE-VTSS 3-flute end mill.

4. Tool Geometry Optimal for Sliding Head Lathes

Space inside the sliding head lathe is limited. Depending on the positioning of the tool changer and workpiece, sometimes a cutting tool cannot be used as is based on its overall length.

During the development process of the AE-VTSS, sliding head lathe manufacturers were surveyed regarding the optimum overall length of end mills. Based on these feedback, the AE-VTSS is designed to feature an overall length of 50 mm or less.

5. DUARISE Coating for Long Tool Life

The AE-VTSS end mill employs OSG’s DUARISE coating with excellent lubricity, wear resistance, superior friction-resistance and high oxidation temperature qualities.

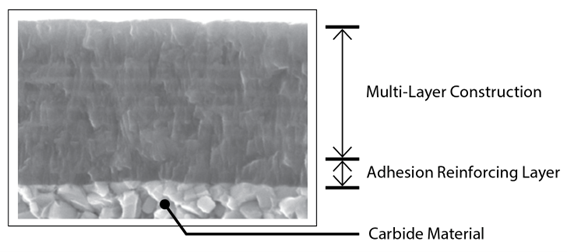

Figure 6. Composition of OSG’s DUARISE coating.

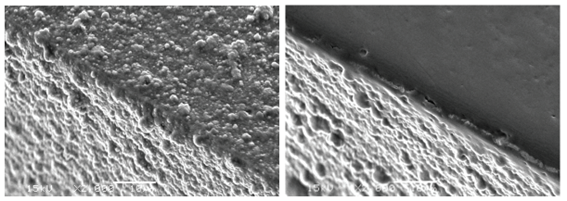

Figure 7. From left, conventional coating and the DUARISE coating.

The DUARISE coating is composed of a heat resistant layer, a low friction layer, and an adhesion reinforcing layer as depicted in figure 6. Its multi-layer construction suppresses thermal cracks to prolong tool life. The surface of the coating is smoothed to remove granular irregularities called droplets to improve the quality of the machined surface as illustrated in figure 7.

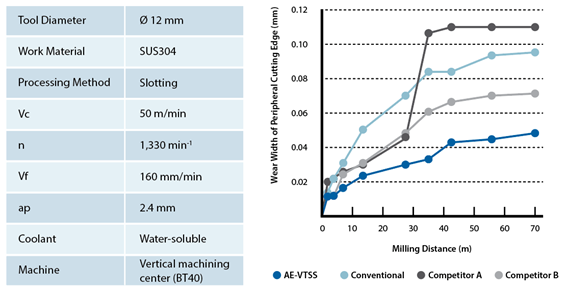

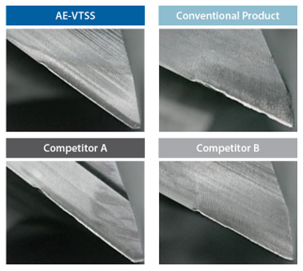

Figure 8. Wear resistance comparison

Figure 8 illustrates the superior tool life of the AE-VTSS. In the cutting trial, wear wide of the peripheral cutting edge by four end mills are measured after milling 70 m in SUS304. The AE-VTSS demonstrates high durability with minimal wear whereas the other end mills exhibit significantly greatly wear.

The AE-VTSS is one of OSG’s latest milling innovations optimally designed for sliding head lathes to achieve efficient, precise, and repeatable stable cutting of unattended machining over long periods to reduce production costs. The AE-VTSS is designed to support a wide range of milling operations in stainless steel, cast iron, carbon steel, alloy steel and hardened steel (up to 40 HRC). The new offering is available from diameter 3 mm up to 12 mm, with a total of seven items, and will continued be expanded to better fulfill evolving needs.

For more information on the AE-VTSS anti-vibration carbide end millcompatible with sliding head lathes

Stable and high efficiency in small diameter deep-hole applications.

- Hiroyuki Amano, OSG Corporation Applications Engineer (Drill Development Division)

OSG Corporation has recently released the ADO-MICRO – the company’s first small diameter carbide drill with oil holes designed for stable and high efficiency drilling in deep-hole applications. The sense of size upon hearing the phrase “small diameter” will be understood differently among users in the manufacturing industry.

The ADO-MICRO has a lineup of drill diameters from 0.7 mm up to 2 mm for drill lengths of 2xD and 5xD, and diameter 1 mm to 2 mm for drill lengths of 12xD, 20xD and 30xD. The product name ADO-MICRO may seem to be associated with the unit prefix micro (µ), but it was named to simply imply smallness in size regardless of the unit.

For small diameter drilling, options such as carbide drills and HSS drills using external coolant are available. However, today’s machining needs require greater stability, higher efficiency and longer life than ever before. There is no exception in small diameter deep-hole applications, with growing needs for coolant-through small diameter drills.

Tool Geometry

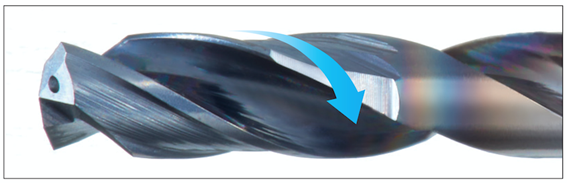

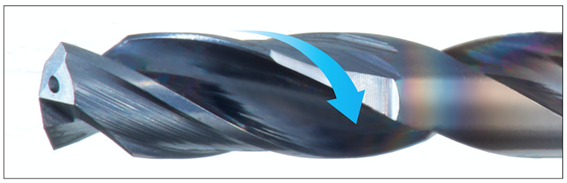

One of the keys for successful small diameter drilling is trouble-free chip evacuation. As illustrated in figure 1, chips generated at the tip of the tool flow in the direction of the blue arrow. However, if there is insufficient space in the flute, cutting chips cannot evacuate smoothly, which causes the drilling accuracy to deteriorate and increases the probability of tool breakage. Therefore, by providing a wider flute specification at the area where the tip of the blue arrow locates, as depicted in figure 1, cutting chips are able to be discharged without difficulty, leading to stable machining.

Figure 1. Extended flute

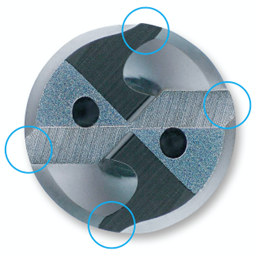

In addition, the ADO-MICRO employs a unique double margin geometry (as depicted in figure 2) in all sizes to enable stable machining even in deep-hole applications. In order to ensure the rigidity of the cutting edge, the margin is set to the minimum necessary length. However, micro sludges can be easily accumulated around the outer periphery of the cutting tool, which is a key cause of abrupt tool breakage. To resolve this challenge and to achieve an overall balance, an extended flute configuration is incorporated to provide sufficient exit room as shown in figure 3.

Figure 2. Four support points with the double margin design

Figure 3. Exit room at end of margin

Oil Holes

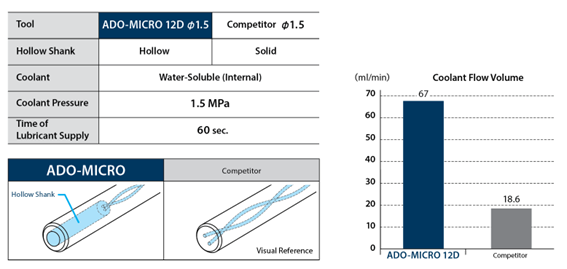

The ADO-MICRO features a straight hollow shank design where coolant is injected in addition to the two spiral oil hole paths. This configuration increases coolant discharge from the tool tip. Without the hollow shank configuration, greater pressure is required in order for the coolant to pass through the thin oil hole paths. With the hollow shank feature, pressure loss is reduced, which increases the coolant flow volume. As illustrated in figure 4, with a higher coolant flow rate, cutting chips can be more effectively evacuated, thereby enabling stable machining.

Figure 4. Relationship between shank structure and coolant flow volume

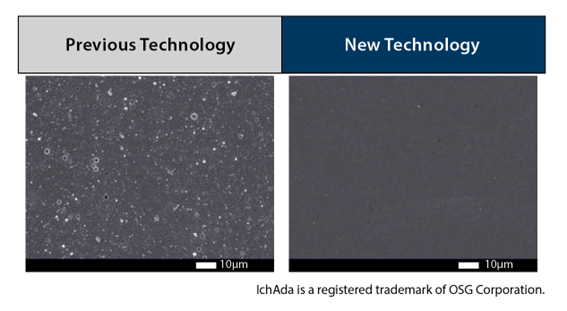

OSG’s Latest Coating Technology: IchAda Coating

Another key element for achieving stable processing in small diameter deep-hole application is coating technology. The role of tool coating is to provide wear resistance and heat resistance to prolong tool life, which is particularly important to small diameter tooling. As illustrated in figure 5, the coating surface by conventional technology is not smooth, which may interfere with the performance of chip evacuation. OSG’s latest IchAda coating, on the other hand, provides excellent surface smoothness in conjunction with high wear resistance and heat resistance to enable small diameter tools to achieve long tool life by improving adhesion.

Figure 5. Surface of coating

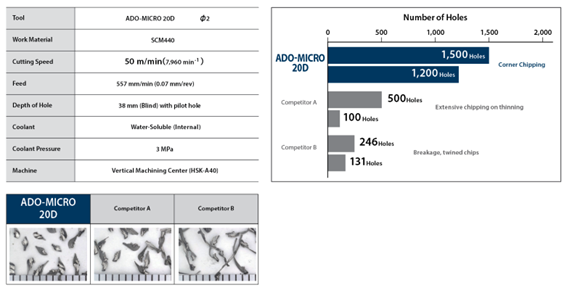

Cutting Data

Figure 6 demonstrates a comparison of tool life between the ADO-MICRO and two other tooling manufacturers’ products in the machining of SCM440. The competitor drills have chipped or have broken at the initial machining stage. The ADO-MICRO, on the other hand, was able to achieve long tool life stably due to its superior chip evacuation capability by breaking chips into small and manageable pieces.

Figure 6. Stable and long tool life in SCM440

The ADO-MICRO demonstrates stable performance even in difficult-to-machine titanium alloy applications. As shown in figure 7, the competitor drill struggled with chip evacuation, thus requiring step processing. However, with the ADO-MICRO, step processing can be eliminated while achieving approximately five times the drilling efficiency. The ADO-MICRO was still in good shape after doubling the competitor drill’s tool life, allowing it to be used on other applications.

Figure 7. Efficiency improvement in titanium alloy

The ADO-MICRO’s unique tool geometry and OSG’s original IchAda coating allow non-step drilling even for deep-hole applications, enabling high processing efficiency. By eliminating common complication in small diameter deep-hole drilling, the ADO-MICRO is able to excel with stable performance in a wide range of work materials including stainless steel. In addition to standard stock items, OSG also offers customization services with tailored solutions for each and every manufacturer’s specific machining needs.

For more information: Click Here

(1)_1000.png)

We are pleased to announce the expansion of our PHOENIX® PDZ offering with the addition of the NEW PDZ-3D indexable flat drill.

The following list numbers are associated with the OSG PHOENIX® PDZ Series Expansion:

- NEW! List #52514 OSG PHOENIX® PDZ-3D (inch)

- NEW! List #78538 OSG PHOENIX® PDZ-3D (metric)

The PHOENIX® PDZ indexable flat drill offers the following features & benefits:

✓ Flat bottom cutting-edge configuration is compatible with a wide range of applications - drilling, counterboring, inclined surfaces

✓ Enhanced muscle breaker allows for superior chip breaking capability during drilling, counterboring and turning

✓ High precision finishing on flutes improves rigidity, efficient chip evacuation and reduces cutting force

✓ Available in Inch and Metric sizes

We are announcing the phase out and discontinuation of the following list numbers:

Limited quantities of the above products continue to be available, while supplies last.

_1000.png)

We are pleased to announce the expansion of our HY-PRO® CARB VGM end mill series with the addition of the NEW VGM3-AL! The HY-PRO® CARB VGM3-AL is a is a series of Variable Geometry end mills for High Speed Machining in Aluminum and Non-Ferrous Materials.

The following list numbers are associated with the NEW VGM3-AL series:

- NEW! List #VGM3-AL

The HY-PRO® CARB VGM3-AL end mill offers the following features & benefits:

• Center Cutting - 3 cutting edges to center; ideal for plunging and ramping.

• Variable Index - Reduces vibration during machining.

• Unique Flute Geometry - Maintains excellent cutting edge sharpness and tool rigidity

OSG USA, Inc. promotes Andrew Matt to Vice President of Human Resources

St. Charles, IL- September 1, 2023

Andrew Matt, the former Director of Human Resources, will be responsible for leading the development and execution of Human Resources strategies for OSG USA, Inc.

“I am very excited to support OSG USA, Inc. in my new role by continuing to evolve the role of human resources within the organization. I’m committed to ensuring that HR becomes the collaborative partner to support our journey of innovation and excellence.”

Andrew started his career at OSG in 2020 as Regional Human Resources Manager, and prior to his career with OSG, Matt was an Executive Director of Human Resources and Organizational Development with BathWraps (RHT, Inc.) and originally began his Human Resources career with United Stationers (Essendant) as their Manager of Performance Improvement and Training in 2000.

Andrew earned his Masters in Business Administration from Marquette University in 1994 after earning Bachelor of Science degree in Organizational Management and Marketing from Marquette University. Andrew is a Senior Certified Professional (SHRM-SCP) since 2020. He is a longtime Chicago area native growing up in Riverside and residing in Westmont with his wife and three children.

Ultra-machining efficiency and stability in steel applications

- Takahiro Yamamoto, OSG Corporation Applications Engineer (Drill Development Division)

Three-flute drills are commonly employed in manufacturing. However, they are mostly used in the processing of materials with short cutting chips and low cutting resistance, such as cast iron, ductile cast iron and aluminum alloy. Three-flute drills are sometimes advertised to be suitable for steel materials such as carbon steel, alloy steel and mild steel. However, with a smaller chip room geometry than 2-flute drills, the cutting thrust resistance in 3-flute drills is also greater.

Due to constraints in workpiece configuration, equipment and setup, conventional 3-flute drills often are unable to maximize both speed and precision as advertised. Moreover, in steel processing, the strength of the work material and viscosity are high, making chip separation and stable processing a challenge. With high thrust force and poor chip evacuation, sudden machining troubles such as tool breakage and chipping are common headaches of 3-flute drills.

To help manufacturers maximize productivity, OSG has recently introduced a new revolutionary drilling innovation – the ADO-TRS – nicknamed as the ‘Triple Revolution’ drill, for ultra-machining efficiency and stability in steel materials.

Features of ADO-TRS ‘Triple Revolution’ Drill

There are three major features that enable the ADO-TRS to stably process steel applications.

The most notable key feature is the newly engineered R gash geometry (pat. P) as illustrated in figure 1.

Figure 1. ADO-TRS’ unique R gash geometry enables low cutting resistance and creates short and compact chips stably.

The optimized R shape geometry is designed to control chip flow direction to facilitate trouble-tree chip-evacuation. With this new feature, the ADO-TRS is able to significantly improve chip separation even in steel materials by breaking them into small pieces and consistent shape. In addition, this new geometry can reduce cutting resistance (thrust resistance), by as much as 30 percent versus conventional tooling, enabling it to outperform even 2-flute drills in high-feed processing with minimal cutting resistance.

The second key feature of the ADO-TRS is its wide chip pocket configuration.

In 3-flute drills, chips are difficult to be discharged from the center of the drill. The ADO-TRS employs a wide chip room flute geometry to improve chip ejection. Combined with the R gash specification, chips are curled for greater separation capability, which leads to smooth and stable chip evacuation.

Last but not least, the ADO-TRS is coated with OSG’s original EgiAs coating for high durability. The EgiAs coating is consist of overlapping nano-periodical layers and wear-resistance layers, engineered to suppress the propagation of cracks that are likely to occur during drilling. The wear-resistance layer is composed of multiple hard layers; while the nano-periodical is a combination of hard and soft layers. With a mixture of hard and soft layers, internal stress can be relieved, allowing the EgiAs coating to achieve both high wear resistance and extreme toughness to ensure stable and consistent tool life under aggressive cutting conditions.

Cutting Data

1. Excellent Chip Formation and Evacuation in Steel Applications

Two of ADO-TRS’ most notable benefits are its superior chip management and low resistance drilling capability in steel materials.

SCM440 (raw) is one of the more viscous materials among steels. When processing this material with MQL, chips generated by conventional 3-flute drills and 2-flute drills are elongated as depicted in figure 2. As depicted in figure 3, the conventional 3-flute drill is unable to break chips into small pieces. As a result, remnants of elongated chips remain in the flute of the drill. The ADO-TRS, on the other hand, is able to demonstrate excellent chip form consistently as shown in figure 2.

Figure 2. Chip shape comparison in SCM440.

Figure 3. Condition of the conventional 3-flute drill after processing SCM440.

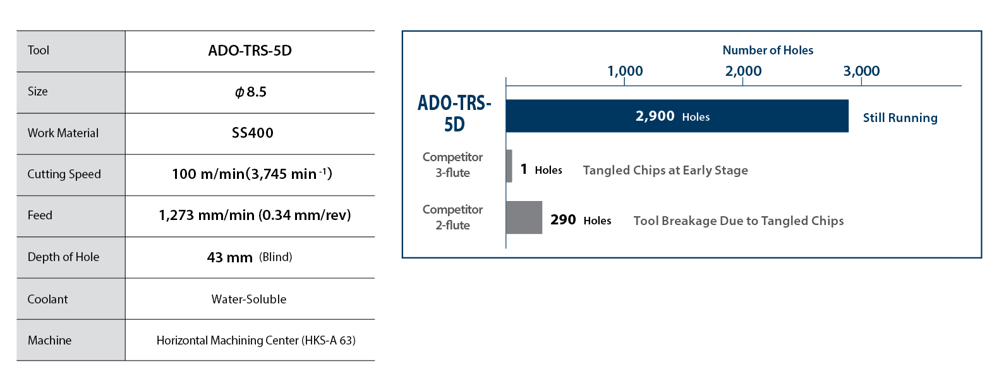

Figure 4. Chip shape comparison in SS400

Figure 5. Tool life comparison in SS400

Moreover, in the processing of SS400 using water-soluble coolant, sudden tool damage and chipping caused by tangled chips are prone to occur. The stability in chip formation and evacuation is a key factor for achieving stable processing in mild steel SS400, which is particularly prone to chip problems. As illustrated in figure 4 and figure 5, the ADO-TRS demonstrates overwhelming chip separation capability and long tool life even in the processing of SS400 in comparison to the conventional 3-flute drill and 2-flute drill.

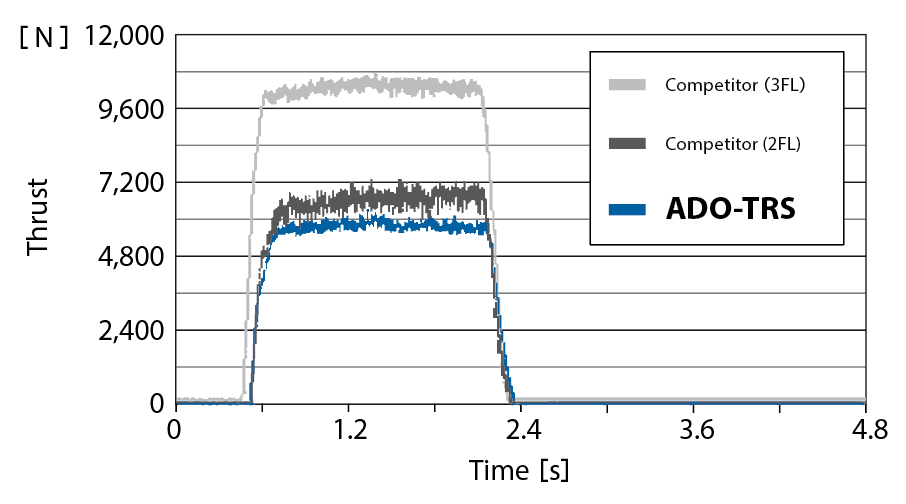

2. Low Resistance Drilling

Next, figure 6 illustrates a comparison of cutting resistance when processing under the cutting condition depicted in figure 2.

Figure 6. Cutting resistance (thrust resistance) comparison in SCM440.

As shown in figure 6, the ADO-TRS is able to reduce thrust resistance by approximately 35 percent versus conventional 3-flute drills, and generated even less overall thrust resistance when compared to a standard 2-flute carbide drill, which has one less flute and larger chip rooms. Under identical cutting condition, the ADO-TRS is able to achieve the lowest thrust resistance.

Due to high cutting resistance inherent in conventional 3-flute drills and the various constraints present in processing environment, such as the machine, workpiece geometry, work fixture, etc., conventional 3-flute drills are often unable to maximize high-feed performance and precision. The ADO-TRS, on the other hand, excels in wide range of cutting conditions, truly reflecting its versatile capability.

Next, we will evaluate the performance of the above features combined with OSG’s original EgiAs coating in the following case study, where the ADO-TRS is able to demonstrate long tool life and stable processing in a crankshaft made of alloy steel. In terms of shape, although the work holding force (clamp) at the time of processing is not high, the effect of the low cutting resistance of the ADO-TRS is able to surpass the carbide 2-flute drill with greater feed-rate. As shown in figure 7, the ADO-TRS is able to achieve higher efficiency and significantly reduce processing time versus the competitor 2-flute drill.

Figure 7. Case study of machining time and tool life improvement in the processing of an automotive crankshaft.

As depicted in this case study, the ADO-TRS is able to demonstrate exceptional stability, high-productivity, long tool life in steel materials, which conventional tools are challenged by instability. Furthermore, with capabilities to resolve common challenges of 3-flute drills such as high thrust force and poor chip evacuation in steel applications, the ADO-TRS is setting a new standard for 3-flute drills with reliable performance never witnessed before in the cutting tool sector.

The ADO-TRS’ unique R gash geometry feature has also been applied to OSG’s ADO 40xD and 50xD carbide drills with through coolant for highly efficient deep-hole drilling. The R gash geometry enables super low cutting resistance and exceptional chip control, optimized for superior performance in ultra-deep-hole applications. This geometry has proven success not only in 3-flute drills, but also in 2-flute drills. OSG will look to apply its superior tooling geometry to other products to further enhance productivity, tool life, stability and precision.

For manufacturers who are especially struggling with chip evacuation problems in steel applications, look to the ADO-TRS to experience ultra-machining efficiency and stability.

The ADO-TRS is available from diameter 3 mm up to 20 mm, in processing depth of 3xD and 5xD, and is suitable for applications in carbon steels, alloy steels, mild steels, cast iron and hardened steels.

Photo Captions

ADO-TRS.The ADO-TRS ‘Triple Revolution’ is OSG’s latest drilling innovation for ultra-machining efficiency in a wide range of materials. Its unique R gash geometry enables high thrust resistance and exceptional chip control, which are common challenges of 3-flute drills.

ADO-40xD 50xD. The ADO-TRS’ unique R gash geometry feature has also been applied to OSG’s ADO 40xD and 50xD carbide drills with through coolant for highly efficient deep-hole drilling. The R gash geometry enables super low cutting resistance and exceptional chip control, optimized for superior performance in ultra-deep-hole applications.

AE-TL-N DLC Coated Carbide End Mill Drives Greater Efficiency in Aluminum Part Processing

Founded in 1968, Ross Industries, Inc. is a specialist in food processing and packaging solutions. Some of its key products include meat tenderizers, antimicrobial intervention systems, chilling and freezing equipment, formers and presses, slicers, macerators, tray sealing equipment, and more. All Ross systems are designed to help processors streamline food manufacturing and packaging functions to improve quality, productivity, and food safety while minimizing waste. With more than 50 years of industry expertise, Ross Industries has built an international reputation as one of the world’s finest food processing and packaging system providers. Employing approximately 100 staff, Ross Industries’ manufacturing plant is located in the city of Midland, Virginia, USA, with an estimate production area of 80,000-square-feet.

Founded in 1968, Ross Industries, Inc. is a specialist in food processing and packaging solutions. Employing approximately 100 staff, Ross Industries’ manufacturing plant is located in the city of Midland, Virginia, USA, with an estimate production area of 80,000-square-feet.

Recently, Ross Industries was tasked with reducing cycle times on all of its aluminum parts. OSG Territory Sales Manager Frank Twomey has been in touch with Ross Industries through a distributor for about two years ago. In need to optimize productivity, OSG was given with an opportunity to test cut the upper chamber 6061 aluminum alloy part used in Ross Industries’ tray sealers for food packaging.

_1000.png)

A CAD model of the front & back of the upper chamber, a part used in Ross Industries' tray sealers for food packaging.

Ross Industries has been producing these aluminum upper chambers for more than 25 years. Approximately 80 chambers are made annually along with thousands of other aluminum parts. The upper chambers are machined using a Doosan HM 1000 horizontal machining center with CAT-50 spindle taper.

The upper chambers are machined using a Doosan HM 1000 horizontal machining center with CAT-50 spindle taper.

Ross Industries was originally using a competitor 1.5-inch diameter indexable shoulder cutter for the application. The competitor tool was used at a speed of 6,000 rpm (2,358 sfm, 717.8 m/min), a feed rate of 120 ipm (3,048 mm/min), 0.005 ipt (0.127 mm/t), 0.3-inch (7.62 mm) radial depth of cut, 0.375-inch (9.525 mm) axial depth of cut, and at a metal removal rate of 13.5 inch3/min (221.2 cm3/min).

The upper chambers are made of 6061 aluminum alloy.

Upon a detail evaluation of the application, Twomey recommended OSG’s 3-flute 1-inch diameter AE-TL-N DLC coated square end mill (EDP# 86301809). The AE-TL-N DLC coated carbide end mill is extremely effective for non-ferrous materials such as aluminum alloys that require welding resistance and lubricity. With excellent cutting sharpness, it is able to suppress burrs to achieve superb surface finish. The AE-TL-N features a unique flute form to enable trouble-free chip evacuation and a large core design for high rigidity to prevent chattering. Its center cutting edge configuration enables the tool to be used for plunging. Furthermore, with the addition of OSG’s DLC-SUPER HARD coating, long tool life can be achieved. This end mill series is available in square, sharp corner edge and radius types to accommodate a wide range of applications.

The AE-TL-N DLC coated carbide end mill is extremely effective for non-ferrous materials such as aluminum alloys that require welding resistance and lubricity.

The AE-TL-N DLC coated carbide end mill was tested at a speed of 5,125 rpm (1,343 sfm, 408.7 m/min), a feed rate of 231 ipm (5,867 mm/min), 0.015 ipt (0.382 mm/t), 0.14-inch (3.556 mm) radial depth of cut, 1.62-inch (41.148 mm) axial depth of cut, and at a metal removal rate of 52.39 inch3/min (858.5 cm3/min). Cycle time on the upper chambers went from 34.5 hours to nine hours.

By switching to the AE-TL-N, Ross Industries has reduced about 75 percent of cycle time on the upper chambers and is now on average achieving a 150 percent cycle time reduction on other aluminum parts.

By switching to the AE-TL-N DLC coated carbide end mill, cycle time on the upper chambers went from 34.5 hours to nine hours.

“This end mill creates chips so fast that our machines chip conveyors couldn’t keep up,” said Ross Industries Machine Shop Manager Greg Williams. “We had to speed up the conveyors.”

Taken in consideration of factors such as tool change time, machine cost, labor, etc., it is estimated that an annual cost savings of $183,000 can be gained. In addition to the upper chamber part, Ross Industries has also converted all of its aluminum end mills to OSG’s AE-TL-N series in various sizes.

From left, Ross Industries Machine Shop Manager Greg Williams and OSG USA Territory Sales Manager Frank Twomey pose for a photograph with a completed upper chamber.

“With the performance and consistent tool life of the AE-TL-N we are able to run these tools lights out,” said Williams. “In some cases, it is able to achieve as much as four times the metal removal rate versus the competitor tool.”

For more information on OSG’s AE-TL-N DLC coated end mill for non-ferrous materials and Ross Industries

_1000.png)

VGM End Mill Boosts Productivity and Lowers Cost Per Part in Aerospace Bracket Application

Sean McIntosh, OSG USA

Founded in 1951 in Phoenix, Arizona, United States, Allied Tool & Die Co. is a family-owned precision machine and fabrication company that specializes in the manufacturing of quality parts for aerospace, medical, communications and commercial industries throughout the world. Seventy years since its establishment, this privately owned shop has grown with multiple facilities and an estimated 32,000 square feet of manufacturing space in Phoenix, Arizona.

One of the challenges Allied Tool & Die faced recently was the machining of aerospace brackets made of Inconel 718. As is with most shops, machining Inconel 718 is time consuming. Moreover, due to the material's special high strength and heat resistance properties, short tool life is a common obstacle.

In search for performance improvement, Allied Tool & Die CNC Process and Machining Manager Jamie Lerma reached out to his local OSG representative for new solutions. Lerma had worked with OSG previously on a 13-8 stainless steel application by utilizing OSG's HY-PRO® CARB VGM series end mill to achieve high-efficiency milling.

OSG's HY-PRO® CARB VGM is a high performance variable geometry end mill series. Its variable index and unique flute geometry enable the reduction of vibration and chatter, promoting smooth and stable cutting with low cutting forces. With the addition of OSG proprietary multi-layer EXO coating, higher wear and heat resistance is achieved to prolong tool life. OSG's VGM offering features 5-, 6- and 7-flute lineups, and is available with multiple lengths of cut, with both square end and corner radius variations. This series is suitable for carbon steels, alloy steels, die steels, stainless steels, cast iron, nickel alloy, titanium, and hardened steels up to 45 HRC.

For the 13-8 stainless steel application, the VGM end mill dominated the machining result by extending tool life from seven parts to 21 parts per tool. The parts were also completed in half the time and the tool cost is also cheaper than the competitor tool. Lerma was so impressed by the VGM end mill that he decided to apply the tool to the Inconel 718 aerospace bracket application.

Allied Tool & Die was previously using a high feed indexable milling cutter for the Inconel 718 aerospace bracket application. However, the amount of time and money spent on changing the inserts was less than desired. The previous competitor tool was used at 150 SFM (45.7 m/min),0.009 IPT (0.23 mm/t), 0.05 Aa (ap = 1.27 mm) and 0.75 Ar (ae = 19.05 mm). After reprogramming to utilize OSG's 0.5-inch diameter 5-flute VGM carbide end mill with a 0.030-inch (0.762 mm) corner radius and 1.25-inch (31.75 mm) length of cut (EDP# VGM5-0143), the cutting parameters were changed to 250 SFT (76.2 mm/min,

2,548 min'1), 0.0022 IPT (0.056 mm/t,713 mm/min), 0.75 Aa and 0.035 Ar. The application went from a 4-hour cycle time to just one hour and 45 minutes. Allied Tool & Die no longer had to keep stopping the machine to rotate or change inserts, which they were doing four times per part previously. By switching to the VGM end mill, the tool was loaded, and the job did not have to be tended to until the part was completed. In terms of efficiency improvement, Allied Tool & Die estimated that the tool change has generated a cost savings of $6,875 USD on the Inconel 718 aerospace bracket parts. Moreover, with a lower tooling price versus the previous milling cutter, the cost of tooling also decreased by almost $100 USD per part. With the VGM end mill, Allied Tool & Die was able to machine Inconel 718 at an astounding 250 surface feet per minute (76.2 m/min)- a speed that is only commonly seen in

alloy or stainless steels, not HRSA materials.

With the recent successes, Allied Tool & Die's CNC Programmer John Hernandez decided to apply the

VGM end mill into most jobs he programs. Being such a versatile tool, the VGM can be used to machine anything from common carbon steels up to the nickel alloys required by the aerospace industry.

"This VGM end mill saved us a ton of time," said Allied Tool & Die CNC Process and Machining Manager Jamie Lerma, who has started ordering the VGM series end mill to keep in inventory for whatever job comes up.

Learn more about OSG's HY-PRO® CARB VGM end mill here

1. A CAD/CAM model of a part made from 13-8 stainless steel. Image courtesy of Allied Tool & Die.

2. A CAD/CAM model of an aerospace bracket made from Inconel 718. Image courtesy of Allied Tool & Die.

3. A part made from 13-8 stainless steel that was machined by OSG's HY-PRO® CARB VGM end mill

4. An aerospace bracket from Inconel 718 that was machined by OSG's HY-PRO® CARB VGM end mill

_1000.png)

Contact Us

Contact Us  Product Search

Product Search