Paul Garcia, a sophomore at Fenton High School, hurries off to his internship as soon as the final school bell of the day rings. His friends wonder where he is rushing off to.

“Are you going to McDonald’s or something?” they asked.

“No, I have to clock in at 4pm at my internship at OSG,” Garcia replied, and then ran to meet his mother in the school parking lot.

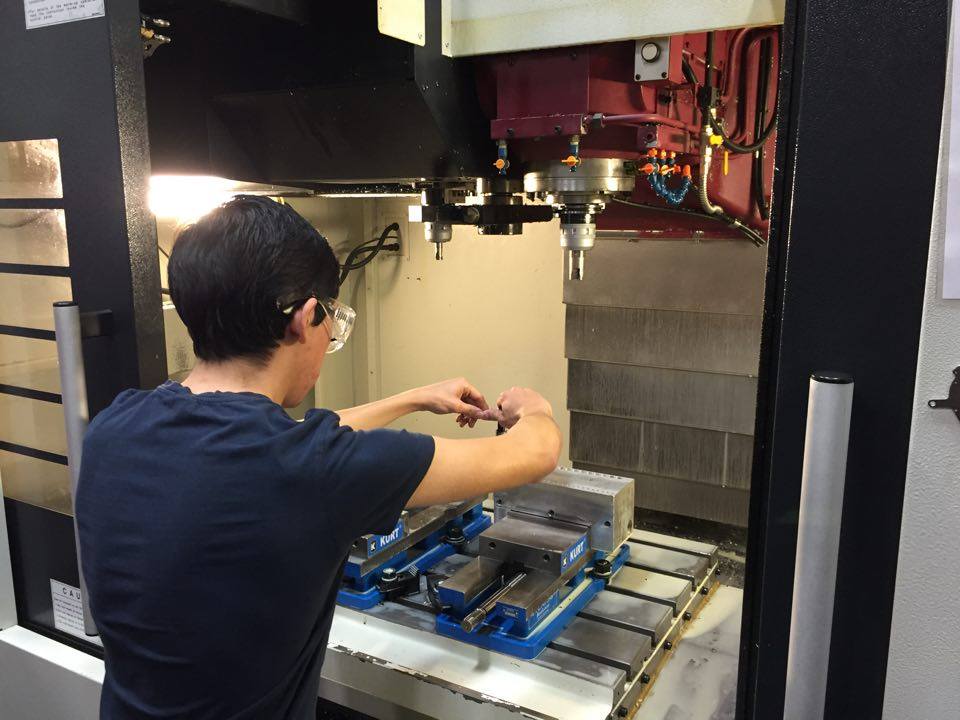

Garcia works as a Jr. Manual Operator intern at OSG. He comes in on Tuesdays and Thursdays from 4pm to 8pm. He works on the manual grinding machines to acquire hands on experience. He also job- shadows OSG CNC operators.

When he is not at OSG, he is a straight- A student and a basketball player at Fenton High School. He participates in PLTW (Project Lead The Way) program where he learns the basics of engineering principles. He is also enrolled in the accelerated classes which have more challenging content and a greater amount of homework than the traditional classes.

“It is challenging to juggle my internship, school work and sports,” said Garcia. “After I get home from OSG around 8:15pm, I sit down at the kitchen table for dinner with my mom, work on my homework and then I finally I go to bed.”

You are probably wondering what is pushing him to do all of this. Paul has a dream, a dream to be a mechanical engineer. He believes that this internship at OSG is a great opportunity to gain manufacturing experience before he pursues his career in engineering.'

In November 2015, Garcia attended the annual Manufacturing Expo hosted by College of DuPage. He met OSG’s HR Generalist, Paul Wilhelm, where he learned about the internship opportunity.

“I thought this was a big opportunity as soon as I heard about it,” said Garcia. “I had to take it before anyone else takes it. It is not every day that I come across this type of opportunity.”

Garcia and his parents are aware of the stigmas the society has toward manufacturing. Garcia himself used to think that manufacturing jobs were tiring and dirty. However, his negative perception was debunked when he learned how much technology OSG uses in the factory and how clean the factory floor is. His family also supports his decision to work in a factory setting.

“My parents are very proud of me,” said Garcia. “I went through the entire hiring process by myself from contacting Mr. Wilhelm to going on my first interview.”

Garcia’s next step is to go attend college and study engineering. He is already thinking about pursuing a Master’s degree in mechanical engineering. Watching a student like Garcia strive for his dream makes us at OSG hopeful and excited for the future of manufacturing. We are committed to helping students acquire additional experiences and skills outside of school and prepare them for their manufacturing careers.

OSG USA, INC. has introduced its highly anticipated 2017/18 Cutting Tool Solutions Catalog in print and digital versions.

The latest catalog edition is over 1,300 pages and features new products including the EXOCARB® ADF flat drills and PHOENIX® PSTW indexable shoulder cutters, and many new expansions to our quality lines such as the EXOCARB® MAX-MINI drills, EXOCARB® WDO drills, PHEONIX® PXD indexable exchangeable head drills and PHOENIX® PFB indexable ballnose end mills.

The 2017/18 Cutting Tool Solutions Catalog can be downloaded digitally from here.

You may also request a free hard copy by contacting OSG Customer Service at 1-800-837-2223.

We announced the release of our new EXOCARB® ADF drills. The ADF combines two operations in one for the drilling of inclined surfaces and counterboring applications.

The ADF was developed with an “all-purpose” concept for superior versatility, reliability and quality for flat-bottom holes. Machining a flat hole traditionally required the use of an end mill and a drill. The ADF enables one-step drilling thereby simplifying machining time and tool management. The drill’s balanced point form improves precision and minimizes the shifting of hole position. Its sharp cutting edge results in low cutting force to minimize burrs even in thin plates. With a wide chip room geometry, trouble-free chip evacuation can be achieved. Furthermore, with the addition of OSG’s new proprietary EgiAs coating, tool life can be prolonged with excellent heat and wear resistance.

The ADF is engineered for a wide variety of drilling applications including inclined surfaces, curved surfaces, counterboring, eccentric holes, thin plates, etc. It is suitable for common materials such as carbon steel, alloy steel, hardened steel (up to 35 HRC) and cast iron. Standard types are available in diameters from 2 to 20 mm; long types are available in diameters from 3 to 20 mm).

Have you used our aerospace tools? Tell us your favorite. Have you participated in our Aerospace Seminars? Let us know what you thought. To continue to shape aerospace dreams, we would love to hear from you about how our tools and seminars helped you! We will be giving away $25 VISA gift cards to everyone who shares a story on our social media sites!

How to Enter

- Comment about your favorite OSG tools or your thoughts about OSG Aerospace Seminars on our contest post

- Only one entry per person

- Tweet us @OSGTOOL about your favorite tools or your thoughts about OSG Aerospace Seminars

- Use our hashtags, #OSGHelpedMe and #OSGforAero to tweet your stories and see what other people say

- Only one entry per person

Submission Period

- Submission period begins at 12pm on Monday, July 18th and ends at 9pm Friday, July 22nd (CT)

- You must comment or tweet during the submission period to receive a gift card

Eligibility

- Our sweepstakes is open to legal residents of United States

Prize

- Everyone who shares a story will receive a $25 gift card

- You are responsible for monitoring your Facebook or Twitter account for prize notification

- If you don't respond to our message within 2 days, or if the prize is returned to us as undeliverable, you will forfeit the prize

Facebook is not sponsoring, endorsing or administering this sweepstakes and Facebook cannot be held liable for anything related to this sweepstakes.

Happy first day of summer! Get your cellphone summer ready with OSG's Tap-Kun wallpaper.

Download from here: https://www.dropbox.com/sh/vs6i1qnbo42luv1/AAB4JUYv7JwCmK1V2QfU_gjLa?dl=0

By Dustin Loschiavo, District Manager

Did you know there are twice as many people wearing braces today than there were 15 years ago? The need for the new and improved orthodontic products has grown rapidly. I recently visited American Orthodontics in Sheboygan, WI, one of the largest Orthodontics manufacturers in the world. They have just introduced the PowerScope, a wire to wire device that eliminates the need for headgear and special bands with more comfort and a better aesthetic appearance.

I spoke with Lee Vogel, Manufacturing Engineer at American Orthodontics, who expressed that they were having a problem with tool life on the right and left side tower mounts. They had recently changed materials per the customer’s request from a 316 stainless steel to a 17-4 stainless steel to extend the life of the device. The machining process involved milling a flat on two sides of round stock using a Citizen bar-feeder lathe. They were using a competitor’s 1/8 – 1/8 – 1/4, 1 ½ 4 fluted end mill. This end mill was taking 10 passes per side running at 4500 RPM and a feed rate of 8 IPM. I suggested that Lee should take less passes and test OSG’s Aero UVX end mill (3/16 – 7/16 - 0.015 CR 4 flute) for his new material application. We set up at 4 passes per side running at 5000 rpm and a feed rate of 16 IPM. This change alone saved 11 seconds per part and the tool life went from 1600 pieces to 6000 pieces per end mill.

As the number of people with braces is expected to increase more in the near future, manufacturers need to keep up with the trends and demands for the improved braces by coming up with new innovations. In order to do so, it is crucial to be flexible and ready to machine any new materials with efficiency. OSG’s Aero UVX end mills changed the game of machining 17-4 stainless steels with efficiency and extended tool life.

*This article originally appeared in the OSG Cutting News Magazine 2015 Medical Edition.

Mark your calendar to visit us at the upcoming shows:

Where: Suburban Collection Showplace, Novi, MI

When: June 15-16, 2016

OSG Booth#: 122

Orthopedic Manufacturing & Technology Exposition and Conference (OMTEC)

Where: Donald E. Stephens Convention Center, Rosemont, IL

When: June 15-16, 2016

OSG Booth#: 644

International Manufacturing Technology Show (IMTS)

OSG is returning to IMTS this year bigger than ever! Be sure to visit us to see our newest innovations from taps to indexable tools. Product presentations are scheduled everyday, and our top experts will share the valuable industry and machining information! Visit our page on the IMTS website to get more information. Stay tuned for more updates about our IMTS booth!

Where: McCormick Place, Chicago, IL

When: September 12-16, 2016

OSG Booth#: W-1779

National Industrial Fastener & Mill Supply Expo (NIFMSE)

Where: Sands Expo & Convention Center, Las Vegas, Nevada

When: October 26-27, 2016

OSG Booth#: 701

“Dirty floors and oily machines?” “That’s my grandpa’s age,” said Yuchieh Lou, a student from Harper College. Manufacturing students from Harper College in Palatine, Illinois received first-hand exposure to today’s manufacturing as a high tech field and hopefully, are considering manufacturing as a viable career option. On Wednesday, April 6th, 14 students who are enrolled in the Manufacturing Technology Program at Harper College visited OSG’s carbide tooling factory in Bensenville for a field trip. This was conducted as part of OSG’s ongoing Manufacturing Day programs to inspire and support the next generation of manufacturing personnel.

Students started the day hearing presentations about OSG and available career paths. Our HR Generalist, Paul Wilhelm, explained to the students that the retirement of baby boomers is opening up positions for the younger generations in manufacturing. However, it is also creating a skills gap between the skills manufacturers are losing but require and the skills younger people have. Today’s manufacturers require new personnel to have more expertise in manufacturing such as STEM (science, technology, engineering and mathematic) skills at an earlier stage of their career to close this gap.

The students also learned about OSG products through tooling demonstrations in our R&D center. Lukasz Gaca, Machining Applications Engineer at OSG, showed various OSG tools in action. Students also tried hand tapping in a block of aluminum to provide them with some hands on experience with tapping tools.

“One of the exciting things about manufacturing is to create something from raw material,” said Dan Jack Combs, a Harper College student.

After the tooling demonstrations, the students were taken on a plant tour. They were able to see OSG’s manufacturing floor in action with more than 60 CNC machines and in-house coating vessels for patented OSG CVD Diamond and AlTiN/TiAlN coating.

“From this visit, I realized that modern manufacturing does require higher technical skills,” said Billy Tsiveriotis, a Harper College student.

Harper College’s manufacturing department focuses on career readiness using a combination of classroom theory and hands on training with state-of-the-art machines that students will likely to encounter in the industry.

“Our goal in the manufacturing program at Harper College is to improve the caliber of students coming out of the program and getting hired by manufactures,” said Aaron Kolb, an instructor of the Manufacturing Technology Program at Harper College. “Manufacturing has become a high-tech career path with many options, and we work hard to make sure our curriculum matches the needs of manufacturers.”

OSG’s production team is hopeful and excited about the future of manufacturing as they interacted with the student and experienced their motivation and interest in manufacturing.

“Some of the students asked me what constitutes the best employees,” said Chuck Abate, Plant Manager of the OSG Bensenville factory. “I stressed teamwork, integrity and ability to continually learn in addition to technical skills.”

In order to help students get additional experiences and prepare for their manufacturing career, OSG offers an internship program at the Bensenville factory.

A new helmet made of composites, Half Cap, was introduced to Major League Baseball (MLB) for its 2016 Spring Training. Boombang, a company based out of Los Angeles, developed the Half Cap which is constructed with fiber composite, an advanced energy-absorbing impact layer, a foam liner and a breathable moisture-wicking cover. About 20 pitchers are trying out the new helmet during training camp.

Photo Credit: Composites Manufacturing

2. Storm proof house with composites

Stevens Institute of Technology in Hoboken, NJ won the 2015 Department of Energy’s Solar Decathlon by designing and constructing “SURE HOUSE” to prevent damage from hurricanes. They incorporated shutters made of composites for “SURE HOUSE” which was the biggest challenge for them. Not only did the shutter have to be lightweight, but also easy to pull down and lock in case of a storm. Utilizing composite materials was their solution as they provide high strength while being lightweight.

Photo Credit: Composites Manufacturing

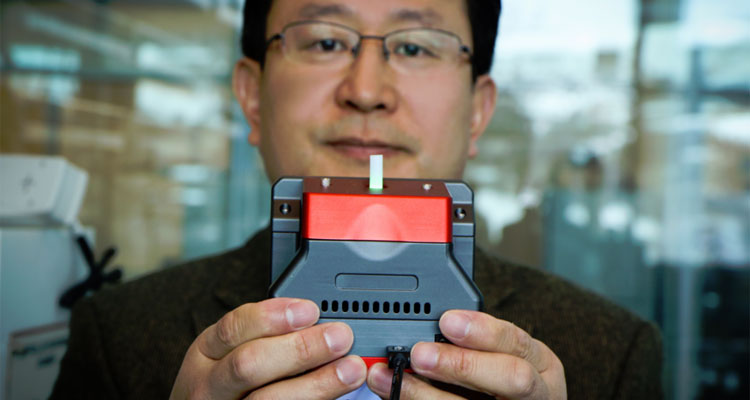

3. Composites could detect bombs

A new type of fiber composite was developed by the engineers at the University of Utah to make a portable scanner for detecting alkane vapor (an ingredient of gasoline, airplane fuel and a homemade bomb). According to them, the only thing available currently for detecting alkane is a large heavy device in a lab. In order to make the portable scanner, they developed a new type of fiber composite with two nanofibers that transfers electrons from one to the other, but when there is alkane, alkane adheres to the materials and prevents electrons to transfer between the materials. The newly developed composite materials will be utilized in the sensor array of the portable scanner.

Photo Credit: Composites Manufacturing

Sources:

http://compositesmanufacturingmagazine.com/2016/02/building-a-storm-proof-house-with-composites/

http://compositesmanufacturingmagazine.com/2016/04/utah-composite-material-detect-bombs/

Contact Us

Contact Us  Product Search

Product Search