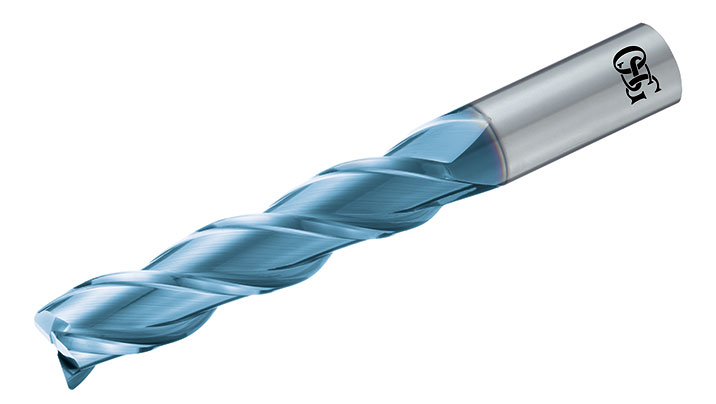

EXOCARB® AERO DLC (2853)

High Speed Carbide End Mills for Aluminum Alloy

Overview

EXOCARB® AERO DLC coating enables the AERO-DLC to produce a superior surface finish even in high speed machining applications.

Features

High Rigidity

Applicable for High Power Equipment

Optimal Flute Shape

Excellent Chip Evacuation

DLC Coating

Excellent Welding Resistance and Lubricity

Sharp Cutting Edge

Exceptional Performance in Aluminum Alloy

Lineup

Series

List 2853 - 3 Flute, Extra Long, Square and Corner Radius, Inch View Offering > View Overview >

Alternate Products

List 2843 - Corner Radius/Square End - Inch View Offering > View Overview >

List 2863 - 2 Flute, Stub Length, Corner Radius, Inch View Offering > View Overview >

List 2873 - Corner Radius/Square - Inch View Offering > View Overview >

List 2874 - Corner Radius/Square - Inch - Coolant Through View Offering > View Overview >

List 2943 - Corner Radius/Square End - Metric View Offering > View Overview >

List 2963 - 2 Flute, Stub Length, Corner Radius, Metric View Offering > View Overview >

List 2973 - Corner Radius/Inch - Metric View Offering > View Overview >

Applications

Aluminum Alloys, Cast Aluminum

Application Guide

| ISO | Work Material | Recommended |

|---|---|---|

| P | Low Carbon Steel : 1010, 1018 |

|

| P | Medium Carbon Steel : 1035, 1045 |

|

| P | High Carbon Steel : 1065 |

|

| P | Alloy Steels : 4140, 4340 |

|

| P | Die Steels |

|

| M | Stainless Steels : 300 |

|

| M | Stainless Steels : 400 |

|

| M | Stainless Steels : 17-4PH |

|

| K | Cast Iron |

|

| N | Aluminum : 6061, 7075 |

|

| N | Aluminum : Casting |

|

| S | Nickel Alloy : Inconel |

|

| S | Titanium : 6AL4V (30HRC) |

|

| H | Hardened Steels : ~35 HRC |

|

| H | Hardened Steels : 35-45 HRC |

|

| H | Hardened Steels : 45-50 HRC |

|

| H | Hardened Steels : 50-70 HRC |

|

good

good  best

best

Contact Us

Contact Us  Product Search

Product Search